Things are taking off!

S&H Co. Ltd., a market leading engineering company based in South Korea, and the manufacturer of the ‘Nuri’ space rocket’s turbo pump, relies on DN Solutions advanced machine tool technologies for its high-precision machining requirements.

Foreword

A critical aspect concerning the successful launch of the Nuri three-stage rocket was that the Korean satellite was launched by a projectile manufactured using domestic technologies.

Approximately 300 private companies were involved in the project, including the Korea Aerospace Research Institute (KARI). One of the principal company’s involved was S&H Co. Ltd., an automotive turbo-engine manufacture, responsible for the manufacture of the Nuri spacecraft’s turbo pumps and for developing a local, high-precision machining resource for producing inducer and impeller parts.

S&H Research Institute Director Min Tae-gi said:

“We are always challenging ourselves to improve our machining capabilities, and DN Solutions has always been there for us.”

“It was an even more meaningful achievement because we succeeded in manufacturing performance-critical projectile components locally, using both domestically-sourced and our own in-house technologies.”

The challenge of machining an automotive turbo-charger

and surprising the world with DN Solutions' Lynx 200 turning center!

In 2000, as environmental regulations for the global automobile market tightened, the demand for turbo-chargers also increased rapidly. At that time, an American manufacturer, which had 50% of the global turbo-charger market, was looking for a new partner to expand its Korean operations.

S&H, which had been producing turbo-charger parts for automobiles since the late 1990s, also heard the news and was spurred into action.

Impeller components, core parts of the turbo-charger, are manufactured using high-precision machining with tolerances as tight as 4μm. It was believed, by some, that such accuracies could only be achieved using specific CNC lathes manufactured in Japan.

S&H responded to the impeller challenge using a DN Solutions Lynx 200 turning center and was confident that it could meet the close tolerances required to machine the part’s interior hole(s): after two to three years’ hard work developing and optimizing the machining process, the company’s decision was vindicated.

As S&H began to manufacture turbo-charger parts, their unit price increased dramatically, causing uncertainty in the market and a need to source innovative and less expensive machined parts and new methods of manufacture. This was a game-changer for S&H.

Even today, S&H produces turbo-charger parts with the Lynx 200. S&H Research Institute Director Min Tae-gi said:

“We were able to secure unparalleled turning technology for machining the turbo-charger parts because of the support provided by DN Solutions’ engineers.”

He added, “If it had been Japanese or German machine tools being used such close collaboration would not have been possible.”

S&H’s automotive turbo-charger business accounts for 90% of its sales turnover. The company is committed to continuous improvement and to investing in advanced machining and manufacturing technologies which it uses to produce a range of high-precision parts that include nozzle rings - a key component for regulating the exhaust gas back-pressure in internal combustion engine vehicles.

Continues Director Min Tae-gi:

“We have completed the development of our nozzle ring hole machining technology by reconfiguring DN Solutions’ V430 machining center so that it has two pallets, enabling it to perform machining on both the left and right sides at the same time.”

He recalled that it was a phenomenal concept, a challenge that the company could not have completed, successfully, without the full support of DN Solutions.

By taking on the previous two projects, S&H was able to confirm that, not only did it have the required advanced technologies in place, but also a proven and proactive relationship with a machine tool manufacturer - itself committed to collaboration and to solving customers’ machining and manufacturing challenges.

The solution was ‘to secure unrivalled technological competitiveness by creating a research center.’

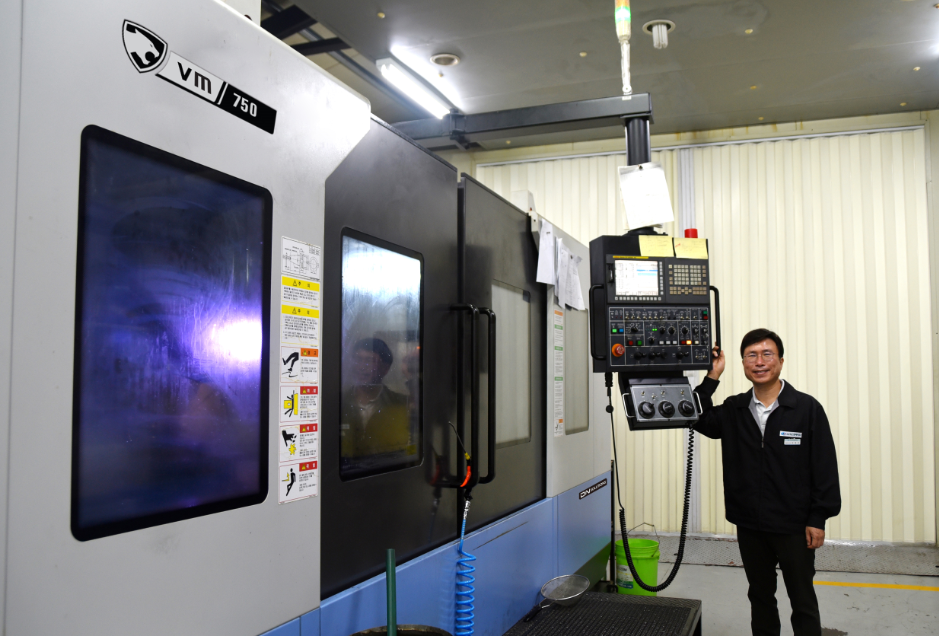

Successful machining of turbo pump parts for the space launch vehicle engine with a VM750 and a NR510.

The turbo pump, the only rotating part that runs at high speed on the Nuri, comprises an inducer, a part that increases fluid pressure; an impeller (rotary blade) that pressurizes the fluid using centrifugal force, and a turbine that powers the turbo-pump.

In 2011, S&H, armed with its turbo-charger part know-how and its proven machining technology, was looking to expand its operations but, after hearing the news that Korea was looking to localize the project with a domestically-manufactured launch vehicle, wanted to become involved.

Director Min Tae-gi said:

“At a seminar we attended with KARI, I learned that the bubbles (cavitations) rushing to the high-speed rotating blades of the turbo-pump were lowering the engine thrust, creating difficulties.”

It was this issue, and the need to resolve it, that led to his involvement in developing a compact and lightweight impeller and inducer.

An ultra-precise 5-axis machining center was needed to machine the inducer, a device that pressurizes the liquid oxygen and fuel that enter the impeller.

Director Min Tae-gi recalled that, “CAM work must precede 5-axis machining, but CAM work was impossible for an inducer with such a complex shape.”

As he believed that these two difficult tasks could not be solved with general purpose, universal machines, he asked DN Solutions for an additional VM750 vertical machining center and a 2-axis rotary indexing table.

In other words, in order to machine the parts, a customized ‘simultaneous 5-axis machine’ was requested.

“Because we already knew that customizing machines could be achieved with the NR510, we asked DN Solutions to configure a simultaneous 5-axis solution for the VM750. DN Solutions mechanical engineers and system personnel visited and worked with us on this project,” added Director Min.

It was not an easy process maintaining constant temperatures and avoiding thermal growth and displacement, but S&H succeeded in machining parts to the level that KARI required. Process realization took about 12 months to achieve.

Director Min Tae-gi recalled, “I was able to cross reference what we were doing with the impeller, because there were examples overseas: but there was nothing similar to refer to with the inducer. We were starting from scratch.”

He continued:

“Taking on manufacturing challenges and producing positive outcomes does not always translate into sales growth or commercial success, but the fact that S&H localized core parts for the launch vehicle using domestic machines was a great achievement and made us very proud.”

The plan is ‘The localization of machining technology is our plan, high added value is our mission.’

Building trust between machine manufacturers and machining companies is the cornerstone of a bigger future.

Director Min Tae-gi said that many of the basic technologies could be localized thanks to the efforts of the many companies participating in the Nuri rocket project.

He also added, “We are proud that S&H led the technology localization project and that we have made a positive contribution in developing a domestic, high added-value and technically-excellent aerospace machining technology resource.

Director Min plans to further enhance the machining competitiveness of turbo-jet engines and airplane engines, whose market is being expanded by S&H based on the turbo technology it has pioneered over the years.

S&H, which is preparing for follow-up launch vehicles after the success of Nuri, tells us that it will have a busy schedule supplying parts for launch vehicle numbers 4, 5 and 6 over the next 12 – 18 months.

In addition, the company is planning to strengthen the performance of existing Nuri parts by developing difficult-to-cut material machining technology that minimizes the use of electric discharge machining (EDM) and welding processes.

Director Min Tae-gi said;

“Because our research institute develops new technologies and is constantly pushing the boundaries – new, different and innovative machines and processes need to be created.

“DN Solutions works in partnership with us to make new and hybrid machines. The company is always receptive and provides a great starting point where we, in conjunction with them, can challenge convention and develop innovative, added-value solutions.

“The performance of the machine tool is important, but so is the machining process. Because DN Solutions know what we're asking for, and because we know DN Solutions's systems and protocols, we've been able to maintain long-term, mutually-profitable relationships with them.”